Regional healthcare services now receiving vital supplies

The University of Central Lancashire (UCLan) is assisting with the response to COVID-19 by manufacturing over 200 items of personal protective equipment (PPE) and vital machine parts for staff at Blackpool Victoria Hospital, and other ambulance, physiotherapy and care home staff.

So far, UCLan has donated over 100 visors to these workers, which have been made using a water jet cutter in the University’s Wharf Building engineering workshops. Using the cutter, the team has been able to make 10 aluminium-framed visors in just 14 minutes, allowing them to make 40 times the number of face visors than they would with a 3D printer. The material also means the visors can be more easily adjusted and disinfected if required.

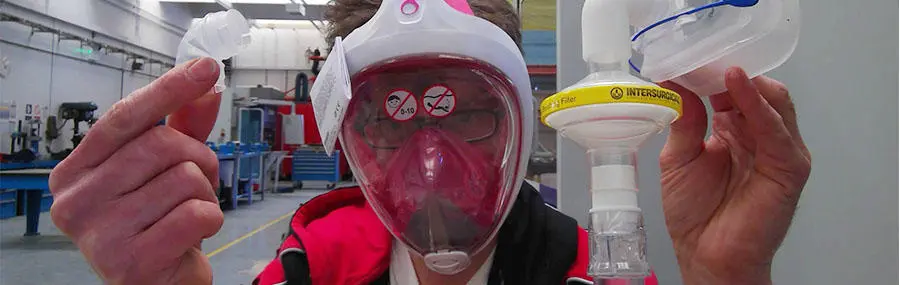

The University team has also designed and 3D printed modifications to continuous positive airway pressure (CPAP) machines, helping to prevent contamination of hospital wards from the exhaled air of COVID-19 patients. With 160 of these nozzles, Blackpool Victoria Hospital are now able to offer 50 more CPAP machines to COVID-19 patients.

"The manufacture and donation of these machine parts and face shields so quickly has helped us to protect our staff and improve capacity in our intensive care units, ensuring we can treat some of the most critically ill patients in our community."

In addition to this, UCLan staff have created 80 leads for invasive blood pressure monitors at Blackpool Victoria Hospital, which measure the arterial pressure of patients – an indicator of how well a COVID-19 patient is responding to treatment. With a global shortage of these leads, the engineering team took the innovative approach of measuring the leads and reverse engineering them, using available components, to produce new compatible connectors using a 3D printer.

Dr Jim Gardner, Medical Director at Blackpool Teaching Hospitals NHS Foundation Trust, said: “We’re so grateful to the team at UCLan for their innovation, expertise and support. The manufacture and donation of these machine parts and face shields so quickly has helped us to protect our staff and improve capacity in our intensive care units, ensuring we can treat some of the most critically ill patients in our community.”

Professor Stjohn Crean, Pro Vice-Chancellor (Research and Enterprise) at UCLan, said: “Our manufacturing team have been exceptional, and have worked day and night to produce as much equipment and parts as they possibly can to help local services. We’re proud to be using our expertise and facilities to support Blackpool Victoria Hospital and other local healthcare providers wherever possible, and will continue to do so throughout this period and beyond.”

A selection of images which show the manufacturing process are available for download.